INDIAN ARMED FORCES CHIEFS ON OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

The insightful articles, inspiring narrations and analytical perspectives presented by the Editorial Team, establish an alluring connect with the reader. My compliments and best wishes to SP Guide Publications.

"Over the past 60 years, the growth of SP Guide Publications has mirrored the rising stature of Indian Navy. Its well-researched and informative magazines on Defence and Aerospace sector have served to shape an educated opinion of our military personnel, policy makers and the public alike. I wish SP's Publication team continued success, fair winds and following seas in all future endeavour!"

Since, its inception in 1964, SP Guide Publications has consistently demonstrated commitment to high-quality journalism in the aerospace and defence sectors, earning a well-deserved reputation as Asia's largest media house in this domain. I wish SP Guide Publications continued success in its pursuit of excellence.

- MoD initiates comprehensive review of Defence Acquisition Procedure 2020, pushes for defence reforms

- G7: The Swansong

- Kalinga Connect: South Asia to Polynesia

- Advanced MRSAM for India for a greater firepower

- Must Credit DRDO for Operation Sindoor, now what is next for defence R&D?

- Operation Sindoor | Day 2 DGMOs Briefing

- Operation Sindoor: Resolute yet Restrained

OEM / Interview

DRDO AIP to be Retrofitted on All Six Indian Navy Scorpene Submarines

Naval Group offers ‘Made in India’ F21 heavy water torpedoes, the French OEM’s India lead Rear Admiral R.K. Shrawat (Retd) discloses in an exclusive interview to Vishal Thapar of SP’s Naval Forces

Chairman and Managing Director (CMD) of Naval Group India Private Ltd Rear Admiral R.K. Shrawat (Retd) indicates that the French company’s engagement with Reliance is limited to the LPD programme. He also suggests that India should avoid going through long and expensive learning curves repeatedly while awarding contracts for major ship building programmes. His remarks are significant ahead of the commencement of the competition to build a new line of submarines under Project 75(I). Rear Admiral Shrawat was earlier CMD of the state-owned MDL, India’s only submarine manufacturer. The full text of the interview:

Vishal Thapar (SP’s): The fourth of the six Scorpene/Kalvari class submarines for the Indian Navy was recently launched. How would you describe the status of the Project 75?

Rear Admiral R.K. Shrawat (RKS): As indicated by Indian Navy and MDL, the P75 programme is well on track. Launch of fourth submarine, Vela on 06 May 2019 was a historic event, as MDL achieved another significant milestone in submarine building program, following up on the launch of third submarine Karanj and the prestigious commissioning of INS Kalvari.

For India, this was the first time a fourth submarine of a series was entirely constructed in India. Now, the trained and skilled MDL team will undertake the integration of the equipment and machinery on-board and thereafter the sea trials will commence. The other two submarines Vagir and Vagshir are scheduled to be launched in succession.

The second submarine is also expected to be handed over to the Indian Navy shortly, while the third submarine is successfully completing its sea trials.

SP’s: What is the extent of indigenisation of the programme?

RKS: The main purpose of Naval Group India Pvt Ltd has been to support the Indian Navy for the ‘Make in India’ activities for Scorpene® submarine equipment, to develop the Indian defence eco-system, as well as to develop design services with talented Indian engineers.

Naval Group’s role in India has not been merely assisting MDL for submarine construction, but also to facilitate localisation. Even though there was no quantified indigenisation requirement in the contract, we did our best efforts to indigenise as many equipment as possible. It is for this reason that Naval Group India Pvt Ltd (previously DCNS India Pvt Ltd) was established in Mumbai to develop a localised industrial eco-system.

Naval Group is so satisfied with the quality standard adhered to (by the Indian supply chain for P75 submarines), that they have taken a step further and outsourced procurement of certain equipment for the French Navy’s latest submarines under construction from these Indian MSMEs

Naval Group, under patronage of MDL and Indian Navy, started in 2009 by identifying more than 500 companies, visited and audited more than 100 of them. Based on such dedicated efforts, 22 Indian companies were contracted under Indigenisation program for P75. Beyond these 22, there are 21 more companies which are also considered fully qualified for further indigenous manufacturing and services. So, we can boast of a strong and sound industrial ecosystem of 43 Indian companies, which is still growing keeping in mind future projects (not limited to submarines).

Also, it is good to remember that the infrastructures, equipment and manpower required to build the P75 submarines were all not available at the time of signature of the contracts in 2005. Such infrastructure had to be created at the expense of huge investment and was completed only in 2012 (wet basin, new cradle assembly workshop...) and trained workforce for key activities of submarine building (for example pressure hull construction) were created.

SP’s: How would you rate the capability of the supply chain in India? What is the major equipment/aggregates/parts for the submarine being sourced from India? Are the Indian suppliers, part of the Naval Group global supply chain?

RKS: Along with MDL, a large number of Indian industrial partners have also invested in Transfer of Technologies and machinery to build equipment in all three of Float, Move and Fight domains for the P75.

We have worked with a range of MSMEs like SEC, Flash Forge, HBL and many more under this program. This has enabled equipment to be locally manufactured in the categories of Float (Hulls, Hatches, Ballast Valves), Move (Steering Consoles) and Fight (Weapon Handling).

Apart from offering HWT Torpedo F21 and future advanced submarines, Naval Group is interested in supporting the Indigenous Aircraft Carrier (IAC) 2, which is at the design stage, LPD and other future naval platforms

Naval Group is so satisfied with the quality standard adhered to, that they have taken a step further and outsourced procurement of certain equipment for the French Navy’s latest submarines under construction, from these Indian MSMEs.

SP’s: After delivering on the Scorpene programme, how does Naval Group visualise its future in India?

RKS: Taking into account Indian Navy’s experience and existing infrastructure at its naval bases, Naval Group is proposing to assist Indian Navy to support the P75 submarines through an onsite team comprising of Indian and French engineers to ensure optimized operational availability of Indian Navy’s P75 submarines. We are also training our local teams under supervision of experts from maintenance domain to perform critical tasks on-board the submarines.

Besides, the Indian Navy has an ambitious modernisation programme and Naval Group would like to support that vision by helping build modern platforms.

SP’s: Which programmes of the Indian Navy is the Naval Group interested in?

RKS: Apart from offering HWT Torpedo F21 and future advanced submarines, Naval Group is interested in supporting the Indigenous Aircraft Carrier (IAC) 2, which is at the design stage, LPD and other future naval platforms with high military requirements and performances. The Group is committed to the Indian Navy and Indian Government for ‘Make in India’ approach of doing business - hence we see a lot of opportunities in the future.

Once capabilities and skilled manpower are developed (by a shipyard), it becomes important to continue utilizing & nurturing these capacities with continuous orders to sustain the knowledge, expertise & resources and thus avoid having to go through another time consuming and costly learning curve again

Naval Group is also interested in offering propulsion equipment for new platforms of Indian Navy and surface ships. We are in the process of identifying and partnering with Indian industries for integration of such equipment locally.

SP’s: What is the status of the Naval Group’s partnership with Reliance?

RKS: The LPD RFP has been issued under a Buy & Make (Indian) category to local shipyards. If RNEL wins, we will provide them with design and some technical assistance to build these amphibious ships.

SP’s: How would you assess private sector capability in the ship-building sector in India?

RKS: For both private sector and public sector shipyards, undertaking any major first of its kind project requires huge investments in infrastructure, equipment, and human resources. Once capabilities and skilled manpower are developed (by a shipyard), it becomes important to continue utilizing & nurturing these capacities with continuous orders to sustain the knowledge, expertise & resources and thus avoid having to go through another time consuming and costly learning curve again. With these factors in mind, private sector has significant potential in certain key areas.

We are aware that Indian Navy wants additional and enhanced performances and capabilities in their future submarine after P75 Kalvari class. AIP and land attack missiles are one of few of such features that are well known to be in the navy’s wish list for P75(I) program

SP’s: Would the core capability continue to vest in the public sector for the foreseeable future?

RKS: The requirements of India in the field of defence manufacture are very important. It makes sense for the government to prop up the private sector through Make in India initiatives, to complement the public sector achievements.

SP’s: How does the Naval Group view India’s Strategic Partnership (SP) Model?

RKS: Regarding the SP norms, Naval Group will continue to apply the same transparent process to transfer the needed technology into the requested domains. Our successful experience in ToTs should allow us to respond and fulfill future requirement formulated by Indian Navy and MOD to be implemented through SP programs. Whatever process is adapted by the Government of India, we will be in a good position to implement it with our experience of indigenisation of the P75 program. We are indeed in a sound position to greatly enhance the indigenous content of submarines constructed in India.

SP’s: What are the key capabilities that the Indian private sector shipyards need to acquire to come up to international standard?

RKS: Some private shipyards have already acquired important skills and experience in shipbuilding and submarine buildings. A few have already manufactured OPVs and training ships. With more orders and thanks to their efficient procurement procedures, these private shipyards should be able to improve their financial position.

SP’s: How has the Scorpene programme impacted the Indian ship-building Industry?

RKS: The Scorpene programme is not only a first of its kind for India but in the world. Indeed, there are no other submarine building projects where the Transfer Of Technology was made for all the submarines to be constructed locally, including the first of class. Submarine construction is one of the most complex industrial endeavours. It requires 20 per cent to 50 per cent more man hours than to build a fighter aircraft.

We believe the AIP developed by the DRDO is a very good system based on sound technologies. We are closely working with DRDO to make this project a success and integrate it with P75 submarines during their refits.

The P75 programme has facilitated local equipment manufacturing and integration, some of which is critical in nature. The quality of the equipment indigenously produced in India is at par with quality of foreign suppliers and in line with the highest requirement of Scropene® submarine. This has definitely given a great confidence and boost to Indian MSMEs who are now in a position to expand in international markets.

SP’s: What are the key new submarine technologies that have emerged since the 2005 Scorpene deal with India?

RKS: We are aware that Indian Navy wants additional and enhanced performances and capabilities in their future submarine after P75 Kalvari class. AIP and land attack missiles are one of few of such features that are well known to be in the navy’s wish list for P75(I) program.

SP’s: Is the AIP offer in terms of transfer of technology still on the table?

RKS: We believe the AIP developed by the DRDO is a very good system based on sound technologies. We are closely working with DRDO to make this project a success and integrate it with P75 submarines during their refits.

SP’s: What is the status of the Naval Group offer for a torpedo for the Kalvari class?

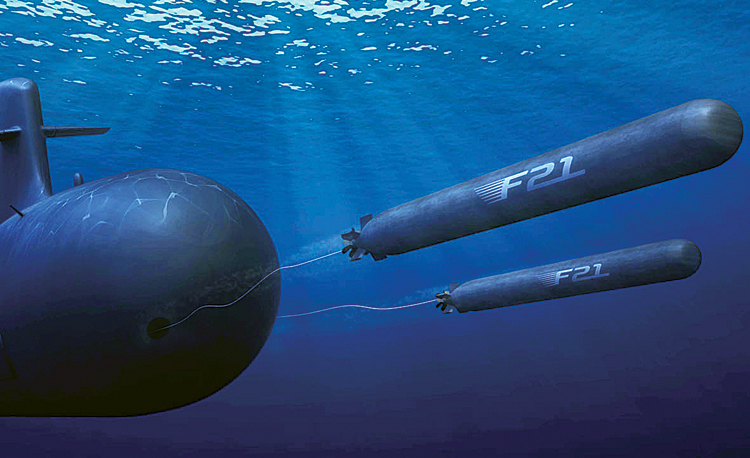

RKS: Naval Group has presented the capabilities of its advanced F21 heavy weight torpedo to the Indian Navy. This torpedo has been developed primarily for the French Navy’s new generation of SSN class submarine Barracuda. With highest safety features, advanced speed and performance, F21 is a much more lethal weapon than other available torpedoes, which mostly use old generation Silver Zinc for their battery technology. It has been successfully tested fired from a French navy Rubis-class SSN.

We are in touch with DRDO as well as indigenous industry to see how best this torpedo (F21) could be offered to the Indian Navy utilizing local capabilities

More than 100 F21 torpedoes have been ordered so far to be integrated on to the French Navy’s Rubis and Barracuda class (SSN) submarines, and also for the Brazilian Scorpene submarines.

We are in touch with DRDO as well as indigenous industry to see how best this torpedo (F21) could be offered to the Indian Navy utilizing local capabilities.